Tips for Finding an Aerospace Metal Fabrication Partner

Choosing the right aerospace metal fabrication partner can be a complex process. While cost is always a factor, it's important to look beyond just price and consider the company’s overall capabilities, experience, and commitment to quality. This guide will help procurement professionals ask the right questions when evaluating potential partners.

A Brief Overview

Some companies specialize in large-scale production runs with lower costs, while others focus on small-batch projects that require high levels of customization. As a procurement professional, it's essential to understand what each potential partner can offer before making a decision. Start by identifying the specific needs of your project and aligning them with the services available from different vendors.

Tips to Find an Aerospace Metal Fabrication Partner

In aerospace manufacturing, precision is everything. The success of any project depends heavily on the accuracy of the parts produced. When searching for a reliable partner, consider the following key questions:

Does the company have on-site testing capabilities? Accurate testing is crucial to ensure that all fabricated components meet required specifications. A good partner should be able to perform thorough inspections in-house and provide immediate feedback, which helps streamline the process and ensures consistent quality.

Can the fabricator build a product from start to finish? While some companies work with multiple partners for different stages of a project, having a single vendor that can handle the entire process from raw materials to final assembly offers significant advantages. It reduces complexity, improves efficiency, and ensures better coordination throughout the project lifecycle.

To assess a company’s efficiency, a visit to their facility is highly recommended. Here are a few things to look out for during your visit:

- Is there a clear and organized project management system in place?

- Does the facility appear clean, well-maintained, and efficiently laid out?

- How does the company plan and manage its workload?

- Is communication between departments effective and timely?

What’s their consultation and engineering experience? A top-tier fabrication partner should act as a strategic collaborator, not just a service provider. They should be able to offer valuable input during the design phase, helping you optimize the manufacturing process and improve the performance of your final product.

Look for a company that avoids one-size-fits-all solutions and instead focuses on continuous improvement. A strong partner will be willing to refine processes over time, ensuring greater efficiency and better results for your projects.

CAMM Metals | CT Aerospace Fabrication

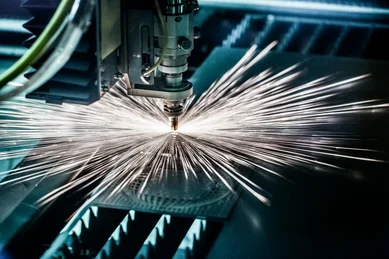

CAMM Metals delivers precision-manufactured aerospace components with tight tolerances, meeting the highest standards of quality and reliability. With a focus on innovation and cutting-edge technology, we work closely with our clients to develop custom solutions that address unique challenges in the aerospace industry.

From concept to completion, every project goes through rigorous quality checks to ensure it meets your expectations. We believe that customer satisfaction is the ultimate measure of success, and we take pride in delivering high-quality products consistently.

If you're looking for a trusted aerospace metal fabrication partner, contact us today at 860-292-6260 or request a quote online. Let’s work together to bring your vision to life.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2546019, 'e7d5e1de-1338-428a-a098-f6228bbbeb1d', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2546019, 'e7d5e1de-1338-428a-a098-f6228bbbeb1d', {"useNewLoader":"true","region":"na1"});

Actmix Pre-Dispersed Rubber Chemicals & Additives (Masterbatch)

Ningbo Actmix Rubber Chemicals Co., Ltd, specializing in manufacturing high quality Pre-dispersed rubber chemicals & additives(masterbatch).

With high quality and competitive price, have exported to Europe, America, Southeast Asia, India, Brazil etc countries and areas.

Actmix Pre-dispersed rubber chemicals & additives(masterbatch) benefits:

- Fast and High predispersibility in rubber compound;

- More accurate weighing & faster mixing;

- Greater stability of active chemicals due to encapsulation;

- Safety of operation - reduced leverls of hazards of skin irritants or inhalation;

- Conformity to EU legislation on handling chemicals;

Actmix Pre-dispersed rubber chemicals & additives(masterbatch) can be application for:

- Automotive rubber industry;

- Technical rubber parts, seal, hose, belt, shock absorber etc.

- Rubber tires;

- Rubber shoes sole

Pre-dispersed Rubber Chemicals & Additives,Pre-Dispersed Rubber Chemicals,Polymer-Bound Rubber Chemicals,Rubber Chemicals Masterbatch

Ningbo Actmix Rubber Chemicals Co.,Ltd. , https://www.predispersedchemical.com