Main Product Precision Parts CNC Machining Parts Aluminum Machining Parts, CNC Machining Metal Parts, CNC Machining

2025-07-19 13:16:11

Model NO.: OEM

Trademark: OEM

Transport Package: Carton

Specification: Customized

Origin: Guangdong, China

HS Code: 8480719090

| Material | Steel, PA, PEEK, POM, TEFLON, PP, Aluminum, Brass, Stainless Steel |

| Certification | ISO9001/TS16949, SGS, TUV |

| Surface Treatment | Anodizing, Oxidation, Nickel Plating, Zinc Plating, Chrome Plating, High Polishing |

| CNC Turning: | Diameter: 1 to 300mm, Length: 1 to 1100mm |

| Tolerance | ±0.005mm to ±0.01mm |

| Inspection Equipment | Calipers, Micrometer, Altimeter, Quadratic Element, Gauge, Roughness Tester |

| Main Equipments | Punching Machines, Welding Machines, Flame Cutting, Laser Cutting, Aluminum Extrusion, Powder Coating Line |

| Drawing Operation | PDF, JPG, AutoCAD, Pro/Engineer, SolidWorks, UG, etc. |

| Industry | Automotive, Electrical, Building, Furniture, Mechanical, Machine Assembly, Computers, Aerospace, OEM/ODM, Electronics |

| Production Range | CNC Turning, CNC Milling, Die Casting, Fabrication, Grinding, Forging, Laser Cutting |

| Professional Team | Over 12 years of experience in metal fabrication |

We Could Do Better With Your Support

| Business Scope |

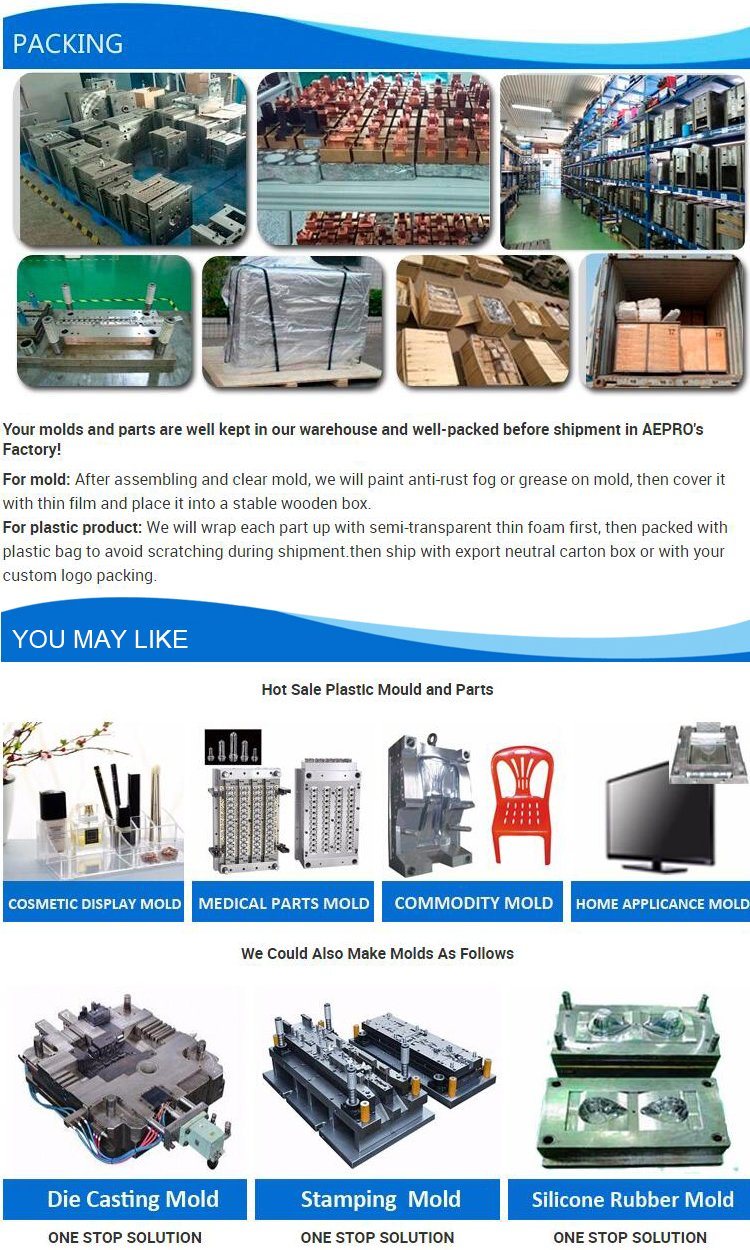

1. One-Stop Service for Molds and Mold Parts; 2. Design and Manufacturing of high precision plastic injection molds, die casting molds, stamping molds, progressive stamping molds, forging molds, silicone rubber molds, CNC machining parts, sheet metal fabrication, tail lift & parts, display parts, European and Japanese truck parts, medical parts, etc. 3. Secondary Finishing Services such as painting, silk-screen, ultrasonic welding, packaging, assembly, etc., to make the product aesthetic as per customer needs, and provide more good solutions for quality. Please kindly visit our product finishing service for details. |

||

| Application |

1. Automobile: New Energy Battery Case and Parts, Car Interior Plastic Case, Auto Inner Parts, Bumper, Door Plate, Auto Lamp, Instrument Panel, Auto Connectors, Electrical Switch, Car Gear, Dashboard Mold, etc. 2. Motorcycle Molds: Motorcycle Mold, Scooter Part Mold, Dune Buggy Mold, ATV Mold, Toy Cart Mold, etc. 3. Commodity Molds: Chair Mold, Stool Mold, Table Mold, Bucket Mold, Basket Mold, Food Container Mold, Storage Box Mold, Dustbin Mold, etc. 4. Industrial Molds: Pallet Mold, Crate Mold, Beer Crate Mold, Paint Container Mold, etc. 5. Electronic: Wireless Receiver Plastic Part, 3G/4G Modem, USB Connector, USB Housing, Mobile Phone Plastic Part, Remote Control, Key-Press; 6. Mechanical: Motor Support Plastic Part, Pump Plastic Part, Mower Plastic Parts Household: Fashion Cup, Juice Cup, Plastic Barrel, Some Small Plastic Parts; 7. Home Appliance: TV Front Cover, TV Rear Cover, Display Cover, Air Conditioner or Refrigerator Plastic Parts, Washing Machine Part. 8. Medical: Hollow Fiber Dialyzer, Deaf-Aid Parts, Medical Instrument Body Plastic Parts, Blood Pressure Meter Parts, Stapler. |

||

| R&D Department |

8+ Senior Engineers and over 18+ Technical Designers, supported by a professional and experienced design team. Our designers are skilled in designing and updating new products and mold structures. Our excellent design capability is highly appreciated by previous customers. Valued Service: We can conduct market research for you and help promote your brand and products in the Chinese market. Successful Projects: New Energy Battery Case and Connector Parts, Display Parts, Tail Lift Parts, Truck Parts. |

||

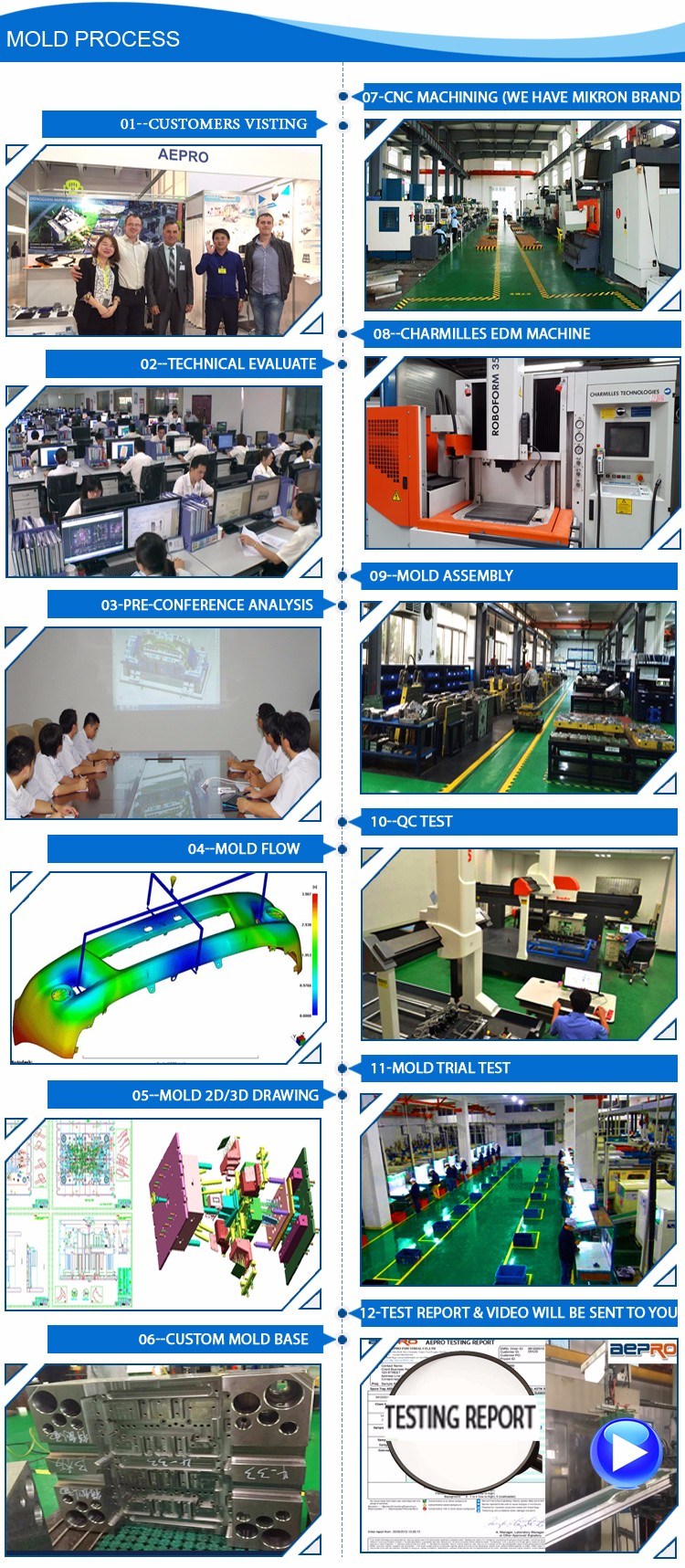

| QC Control |

All projects will be put into DFM Working Flow to ensure product quality, from mold design, mold flow analysis, pre-mold machining review, and a series of testing reports to ensure smooth mold production. We are proud of our mold production process, product quality guarantee, on-time delivery, and have a professional engineering team to support your projects and provide feasible suggestions. Quality System: Our quality team strictly complies with ISO system procedures to control each stage of the process, based on DIN 16742 standards. |

||

| Advanced Processing Equipment |

We have invested over 20 million RMB in imported brand machines and a complete set of production lines: efficient, precise processing, and testing equipment, including: Matched Mold Machine, Deep Hole Drilling Machine, CNC Milling Machine, Drilling Machine, Grinding Machine, Wire Cutting Machine, EDM, Precise Engraving Machine, Lathe Planning Machine, Fly Cutter Machine, Laser Cutting Machine, Mikron/Chamilles, Hans, HAITIAN, etc. Quality System: Certified by ISO9001-2008 for several years, strict quality control adheres to ISO requirements. |

||

Rubber Silicone Machined Parts

rubber machined parts, silicone machined parts, rubber process, silicone process, silicone rubber process

Guangdong Hongwang New Materials Technology Co., Ltd , https://www.hwcncmaterial.com