The Ultimate Guide to Precision OEM Sheet Metal Fabrication

Are you looking to understand the complex process of OEM sheet metal fabrication and the vital role that OEMs play in the manufacturing industry? You've come to the right place! This guide offers a deep dive into the precision, technologies, quality control, customization, and collaborative partnerships involved in the world of OEM sheet metal fabrication.

What You’ll Learn About OEM Sheet Metal Fabrication

This guide will cover the entire OEM sheet metal fabrication process, from design to delivery. You'll discover the technologies used, the importance of quality control, the value of specialization, the role OEMs play in the supply chain, how partnerships are formed, current trends, real-world case studies, sustainability efforts, and how to choose the right OEM partner. The conclusion will highlight the expertise of Atlas Manufacturing.

The OEM Sheet Metal Fabrication Process

OEM sheet metal fabrication is a meticulous process that requires attention to detail at every stage. From initial design and material selection to cutting, forming, and finishing, each step must be executed with precision. The goal is to ensure that the final product meets exact specifications, allowing for seamless integration into the end-use application.

Why Precision and Quality Matter in OEM Processes

Precision and quality are essential in OEM sheet metal fabrication. The ability to meet tight tolerances and produce parts with high accuracy is what sets reputable OEM manufacturers apart. These standards ensure that components not only fit perfectly but also perform reliably within the larger system, contributing to the overall efficiency and success of the final product.

Advanced Technologies in OEM Sheet Metal Fabrication

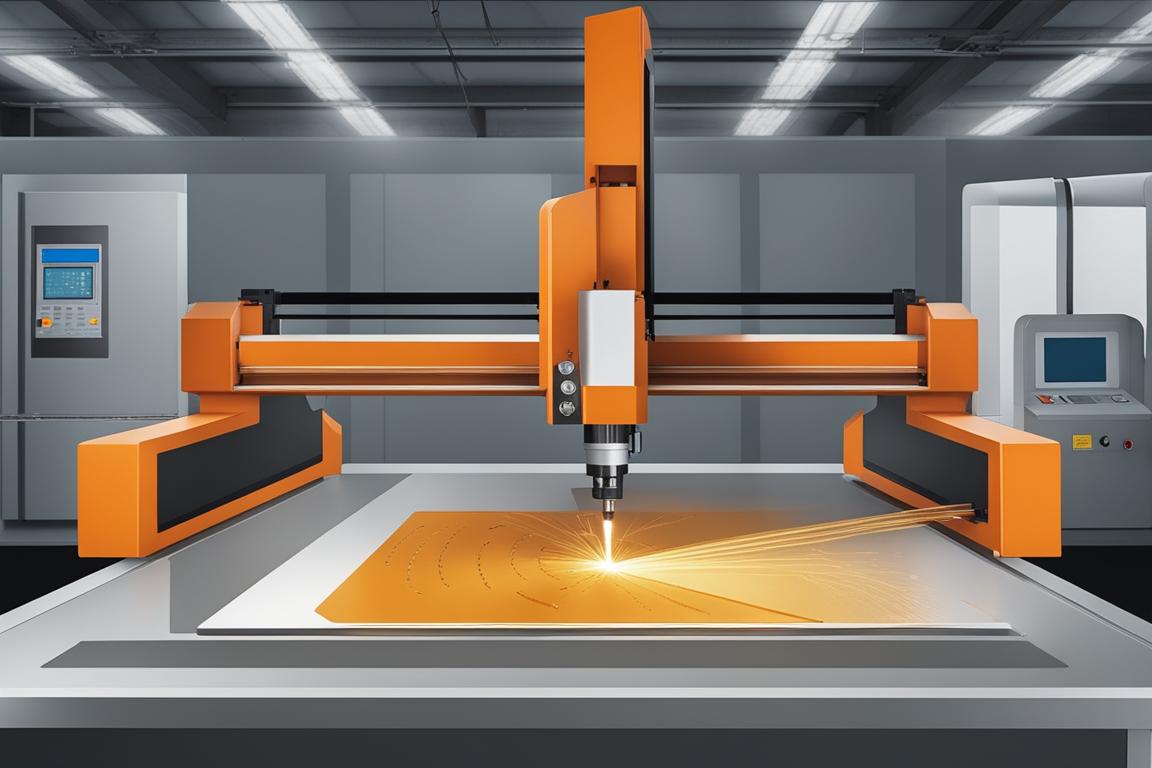

The field of OEM sheet metal fabrication is constantly evolving, driven by advancements in technology and innovative techniques. OEMs use state-of-the-art machinery to achieve higher levels of accuracy, efficiency, and customization.

Key Machinery and Techniques Used

OEMs rely on a variety of advanced tools, including punch presses, laser cutters, welding systems, CNC machining centers, and forming equipment. These technologies enable them to create complex and precise parts that meet the highest industry standards.

| Technology/Technique | Description |

|---|---|

| Punch Presses | Used for precise cutting of sheet metal using different tooling options. |

| Laser Cutting | Enables detailed and accurate cuts on various types of metals. |

| Welding | Essential for joining metal components securely. |

| Machining | Refines part dimensions to ensure high accuracy and precision. |

| Forming | Shapes metal sheets into the desired form or structure. |

Quality Control and Certifications in OEM Fabrication

Quality control is a critical aspect of OEM sheet metal fabrication. Certifications like ISO 9001:2015 serve as proof of an OEM's commitment to maintaining high-quality standards throughout the production process.

The Importance of Quality Assurance

Certifications such as ISO 9001:2015 confirm that an OEM has implemented robust quality management systems. In addition to this, a focus on timely delivery, scalability, and consistent quality ensures that OEMs can meet the needs of their clients while upholding the highest standards of craftsmanship.

Customization and Specialization in OEM Sheet Metal Fabrication

OEMs provide tailored solutions that cater to the specific needs of various industries. Their ability to customize parts makes them indispensable in sectors where unique designs and specifications are required.

Specializing in Custom Parts for Diverse Industries

By focusing on custom parts for industries like agriculture, construction, and material handling, OEMs demonstrate their adaptability and expertise. This specialization allows them to address the unique challenges faced by each sector and deliver solutions that align with the operational needs of their clients.

OEMs and Their Role in the Supply Chain

OEM sheet metal fabricators are essential players in the broader manufacturing supply chain. They supply critical components that are used in the production of a wide range of end products.

Contributing to Multiple Industries

OEMs provide high-quality, precision-engineered parts that serve as the building blocks of many products across different industries. Their role ensures that manufacturers have access to reliable and well-crafted components, which helps drive innovation and efficiency in production processes.

Collaborative Partnerships in OEM Fabrication

Strong partnerships between OEMs and manufacturers are key to successful projects. These relationships foster collaboration, innovation, and shared growth.

Benefits of Strong OEM Relationships

Building long-term partnerships with OEMs brings numerous advantages, including access to specialized knowledge, improved product quality, and more efficient production processes. These collaborations help manufacturers stay competitive in a rapidly changing market.

Trends and Innovations in OEM Sheet Metal Fabrication

The OEM sheet metal fabrication industry is continuously evolving, driven by new technologies and innovative approaches that enhance efficiency and quality.

Embracing New Technologies and Processes

OEMs are always exploring and implementing the latest technologies and methods to improve their capabilities. By staying ahead of industry trends, they can offer cutting-edge solutions that meet the demands of modern manufacturing.

Case Studies and Success Stories

Real-world examples of successful OEM sheet metal fabrication projects showcase the impact and expertise of OEM manufacturers in the industry.

Showcasing Real-World Examples

Case studies and success stories highlight the outcomes achieved through strong OEM partnerships. These examples demonstrate how OEMs can deliver exceptional results that exceed client expectations.

Sustainability and the Future of OEM Fabrication

The future of OEM sheet metal fabrication is moving toward more sustainable practices and environmentally responsible manufacturing methods.

Adopting Eco-Friendly Practices

OEMs are increasingly adopting sustainable materials and energy-efficient processes to reduce their environmental impact. This shift reflects a growing commitment to responsible manufacturing that supports global environmental goals.

Choosing the Right OEM Partner

Selecting the right OEM partner is crucial for businesses looking for reliable and high-quality sheet metal fabrication services.

How to Choose the Best OEM Partner

When selecting an OEM partner, consider factors such as their technical capabilities, industry experience, and adherence to quality standards. A strong partnership with an OEM that values innovation, quality, and customer satisfaction can lead to long-term success.

Conclusion

OEMs are essential in the sheet metal fabrication industry, providing precision-engineered components that support innovation and efficiency across multiple sectors. As the industry continues to evolve, OEMs remain at the forefront of technological advancement and collaborative efforts, ensuring their parts are seamlessly integrated into the manufacturing landscape.

Q & A

What is OEM sheet metal fabrication?

OEM sheet metal fabrication involves producing custom metal parts specifically for original equipment manufacturers.

Who can benefit from precision sheet metal fabrication?

Industries such as automotive, aerospace, electronics, and telecommunications can benefit from precision sheet metal fabrication.

How is precision sheet metal fabrication different from regular fabrication?

Precision sheet metal fabrication involves working with tight tolerances and high accuracy to meet specific OEM requirements.

What makes OEM sheet metal fabrication cost-effective?

Outsourcing to a specialized OEM can offer economies of scale, expert knowledge, and optimized production processes.

How can I ensure the quality of my OEM sheet metal parts?

Look for a manufacturer with ISO certifications, a proven track record, and established quality control procedures.

What if I need custom designs for my OEM sheet metal parts?

A reputable OEM can work closely with you to develop custom designs that meet your specific needs.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "What is OEM sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "OEM sheet metal fabrication involves producing custom metal parts for original equipment manufacturers."}}, {"@type": "Question", "name": "Who can benefit from precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Industries such as automotive, aerospace, electronics, and telecommunications can benefit from precision sheet metal fabrication."}}, {"@type": "Question", "name": "How is precision sheet metal fabrication different from regular fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Precision sheet metal fabrication involves tight tolerances and high accuracy to meet specific OEM requirements."}}, {"@type": "Question", "name": "What makes OEM sheet metal fabrication cost-effective?", "acceptedAnswer": {"@type": "Answer", "text": "By outsourcing to a specialized OEM sheet metal fabrication company, you can benefit from economies of scale and expertise."}}, {"@type": "Question", "name": "How can I ensure the quality of my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "Look for a fabricator with ISO certifications, a proven track record, and quality control processes in place."}}, {"@type": "Question", "name": "What if I need custom designs for my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "A reputable OEM sheet metal fabrication company can work with you to create custom designs that meet your specific needs."}}]}NOXLUB BF2325 is a white, fine texture, long-acting high temperature grease.

The product uses perfluoropolyether (PFPE) as base oil and polytetrafluoroethylene (PTFE) as thickener, which makes it have good medium resistance and can protect parts well.

NOXLUB BF2325 has excellent corrosion resistance and evaporation stability, and excellent lubrication even under high temperature circumstance.

Anti Rust Lubricant,Corrugating Roll Lubricant,Corrugated Machine Lubricant

LLY PACK(foshan) Co.,Ltd. , https://www.llypack.com