Rubber Press Machine From China Manufacturer

1. Application:

The machine is widely used for vulcanizing various rubber and plastic products, both with and without molds. It's ideal for industries like tire manufacturing, rubber goods production, and more.

2. Key Features:

- Movable bolster for better operation flexibility

- Blanking buffer device for safer and smoother working process

- Photoelectric protection system for operator safety

- Digital display and control for precise operation

- Industrial touchscreen monitor for user-friendly interface

- Oil heating or cooling system for temperature regulation

- Ejection device for easy product removal

- Slider safety device for added protection

- Heating and temperature control for consistent performance

3. Working Principle:

The machine features a frame structure with an upward pressing mechanism. Under hydraulic pressure, the piston rises to close the hot plate and apply pressure. When the piston descends (hot plate opens), it’s driven by the weight of the hot plate, platform, and piston, which pushes the working fluid into the reservoir. The oil cylinder is made of nodular cast iron, enhancing compressive strength and wear resistance. A seal ring made from oil-resistant rubber ensures a tight seal during operation.

The combined oil pump provides the necessary pressure to the working fluid, which enters the oil cylinder through a control valve. By adjusting the control handle, the piston can move up or down as needed. The machine uses tubular electric heating components, reducing air pollution and eliminating the need for a boiler. Its design is elegant, structurally rational, and safe for long-term use.

4. Main Technical Specifications:

Model & Specifications |

XLB-400X400X2 |

XLB-500X500X2 |

XLB-600X600X2 |

XLB-750X850X2(4) |

Total Pressure (MN) |

0.25 |

0.50 |

1.00 |

1.60 |

Plate Size (mm) |

400X400 |

400X400 |

600X600 |

750X850 |

Daylight (mm) |

125 |

125 |

125 |

125 |

Layer No |

2 |

2 |

2 |

2(4) |

Piston Stroke (mm) |

250 |

250 |

250 |

250(500) |

Unit Area Pressure (kg/cm²) |

20 |

31 |

28 |

25 |

Main Motor Power (Kw) |

3 |

2.2 |

2.2 |

3 |

Overall Dimension (mm) |

1300X800X1500 |

2400X550X1500 |

1401X680X1750 |

1900X950X2028 |

Weight (Kg) |

1150 |

1300 |

3500 |

6500 |

5. Why Choose Us?

- Direct manufacturer sales ensure quality and timely delivery

- Small plunger diameter difference ensures even pressure distribution

- Equipped with automatic temperature and pressure control, alarms, loading, emergency stop, and digital readout

- Low noise, no oil leakage, and stable pressure

- Hot plate temperature variation within ±1°C, meeting national standards

- Parallelism difference not exceeding ±0.01–0.02 mm

- Customizable heating methods: electric, steam, or oil

- Can be customized according to your specific needs

- Discounts available based on order quantity

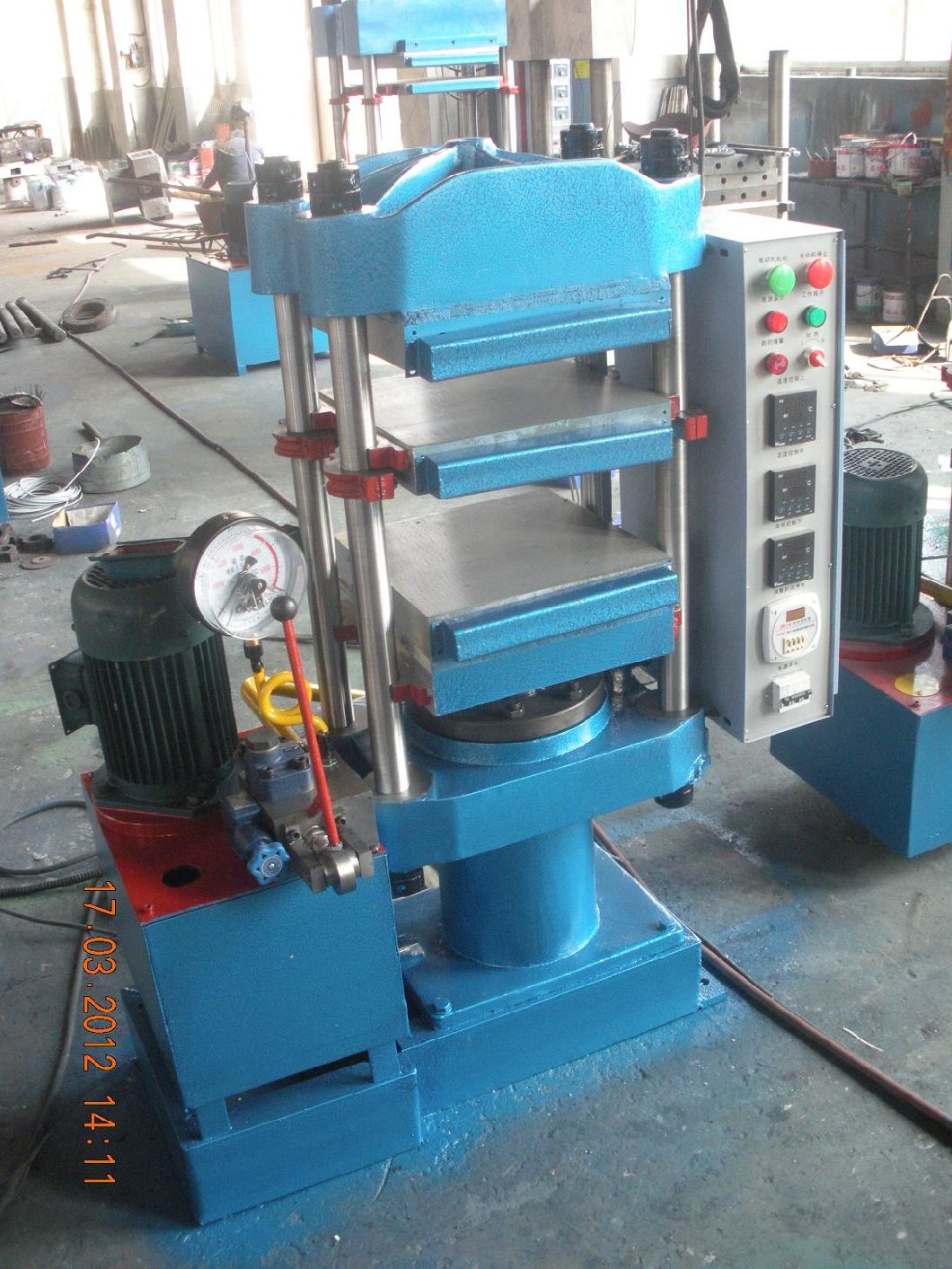

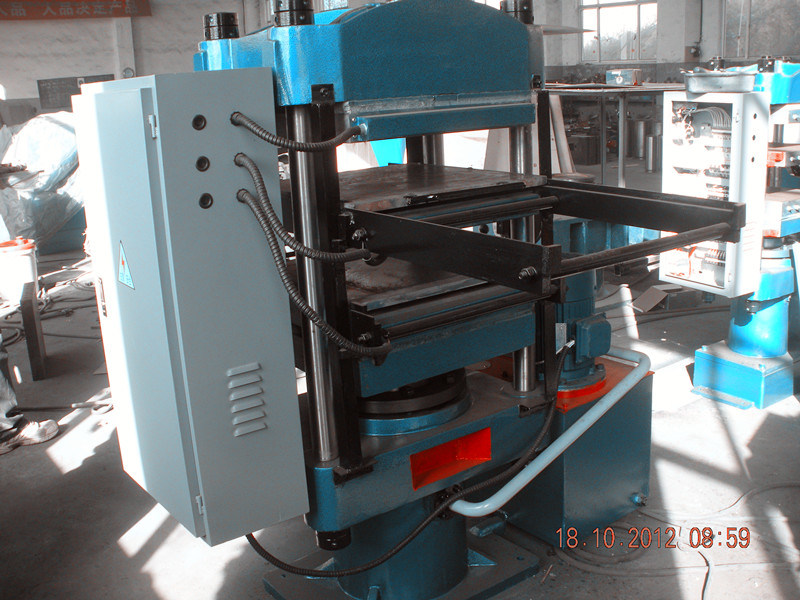

6. Machine Pictures:

2 Layers (3 Hot Plates)

1 Layer (2 Hot Plates)

Digital Screen (Emergency Stop, Auto Alarm)

Optional Pull and Push Mould Installation

Note: When you send an inquiry, please provide detailed requirements such as:

- Desired pressure (50T, 63T, 100T)

- Distance between hot plates (e.g., 125mm)

- Hot plate size

- Voltage preference, and whether you need push/pull molds

- Include your phone number, Skype, Viber, or WhatsApp ID in the email for faster communication

Packaging & Shipping:

Wooden packing or as per client request

Our Services:

- Overseas service: 1-2 technicians will debug and train for 7-14 days at $60/day per person. You are responsible for travel, visa, accommodation, and meals.

- If quality issues occur during warranty (excluding human error), we will replace it free of charge.

- We respond within 24 hours and solve problems via pictures or videos. If unresolved, we can send engineers to your factory.

- We welcome you to visit our factory. We can book a hotel and pick you up at the airport for a tour of our facilities and client operations.

- Logo design: We can create a custom logo based on your provided image.

- Original B/L, commercial invoice, and packing list are available (3 copies via TNT).

- Certificate of origin is also provided to help reduce import taxes.

Company Information:

Qingdao Chaoguangyue Industry Co., Ltd. has strong technical capabilities, advanced techniques, and a strict quality assurance system. Our main products include plate vulcanizing presses, EVA foam vulcanizing presses, open rubber mills, Banbury mixers, extruders, and reclaimed rubber machinery. We also produce non-standard rubber machines according to customer specifications. Our products are sold across more than 20 provinces in China and exported to over 10 countries.

With years of experience, we focus on high-quality and high-standard products. Our philosophy is "survive through quality and technology, win the market with honesty and brand."

Certification: CE, SGS, ISO9001

Welcome to contact us for pricing!

China leading manufacturers and suppliers of Flat Gloss Powder Coating,Flat Black Powder Coating, and we are specialize in Powder Coating Gloss,Powder Coating, etc.

Flat Gloss Powder Coating,Flat Black Powder Coating,Powder Coating Gloss,Powder Coating

Longkou Guomei Decoration Material Co.,Ltd. , https://www.gmcoating.com