Rubber Press Machine From China Manufacturer

1 Application:

This rubber press machine is ideal for vulcanizing various types of rubber and plastic products, including both molded and non-molded items. It is widely used in industries such as tire manufacturing, rubber product development, and industrial component production.

2 Features:

- Movable bolster for flexible operation

- Blanking buffer device for smooth performance

- Photo-electric protection system for enhanced safety

- Digital display and control for precise operation

- Industrial touch screen monitor for user-friendly interface

- Oil heating or cooling system for temperature regulation

- Ejecting device for easy removal of finished products

- Safety device for the slider to prevent accidents

- Heating and temperature control system for consistent quality

3 Working Principle:

The machine features a frame structure with a downward pressing design. Under hydraulic pressure, the piston rises to bring the hot plate into contact for applying pressure. The piston then descends by the weight of the hot plate, platform, and piston itself, which drives the working fluid back to the reservoir, enabling the machine to open. The oil cylinder is made from nodular cast iron, enhancing its compressive strength and wear resistance. An oil-proof rubber seal ring ensures effective sealing during operation. A combined oil pump serves as the power source, providing the necessary pressure for the working fluid. Control valves regulate the movement of the piston, allowing it to rise or fall as needed. The machine also uses tubular electric heating components to reduce air pollution, keeping the workshop clean without the need for a boiler. Its elegant design, rational structure, and convenient control make it a reliable choice.

4 Main Technical Specifications:

Model & Specifications |

XLB-400X400X2 |

XLB-500X500X2 |

XLB-600X600X2 |

XLB-750X850X2(4) |

Total Pressure (MN) |

0.25 |

0.50 |

1.00 |

1.60 |

Plate Size (mm) |

400X400 |

400X400 |

600X600 |

750X850 |

Daylight (mm) |

125 |

125 |

125 |

125 |

Layer No |

2 |

2 |

2 |

2(4) |

Piston Stroke (mm) |

250 |

250 |

250 |

250(500) |

Unit Area Pressure (kg/cm²) |

20 |

31 |

28 |

25 |

Main Motor Power (Kw) |

3 |

2.2 |

2.2 |

3 |

Overall Dimension (mm) |

1300X800X1500 |

2400X550X1500 |

1401X680X1750 |

1900X950X2028 |

Weight (Kg) |

1150 |

1300 |

3500 |

6500 |

5 Why Choose Us?

- Direct manufacturer sales ensure timely delivery and high-quality standards.

- Minimal plunger diameter differences guarantee uniform pressure distribution.

- Equipped with automatic temperature and pressure control, alarm systems, loading functions, emergency stop, and digital readout.

- Low noise, no oil leakage, and no pressure loss.

- Small temperature difference on the hot plate (±1°C), meeting national standards.

- Parallelism difference does not exceed ±0.01–0.02 mm.

- Customizable heating methods: electricity, steam, or conduction oil.

- We can customize machines based on your specific requirements.

- Discounts available depending on order quantity.

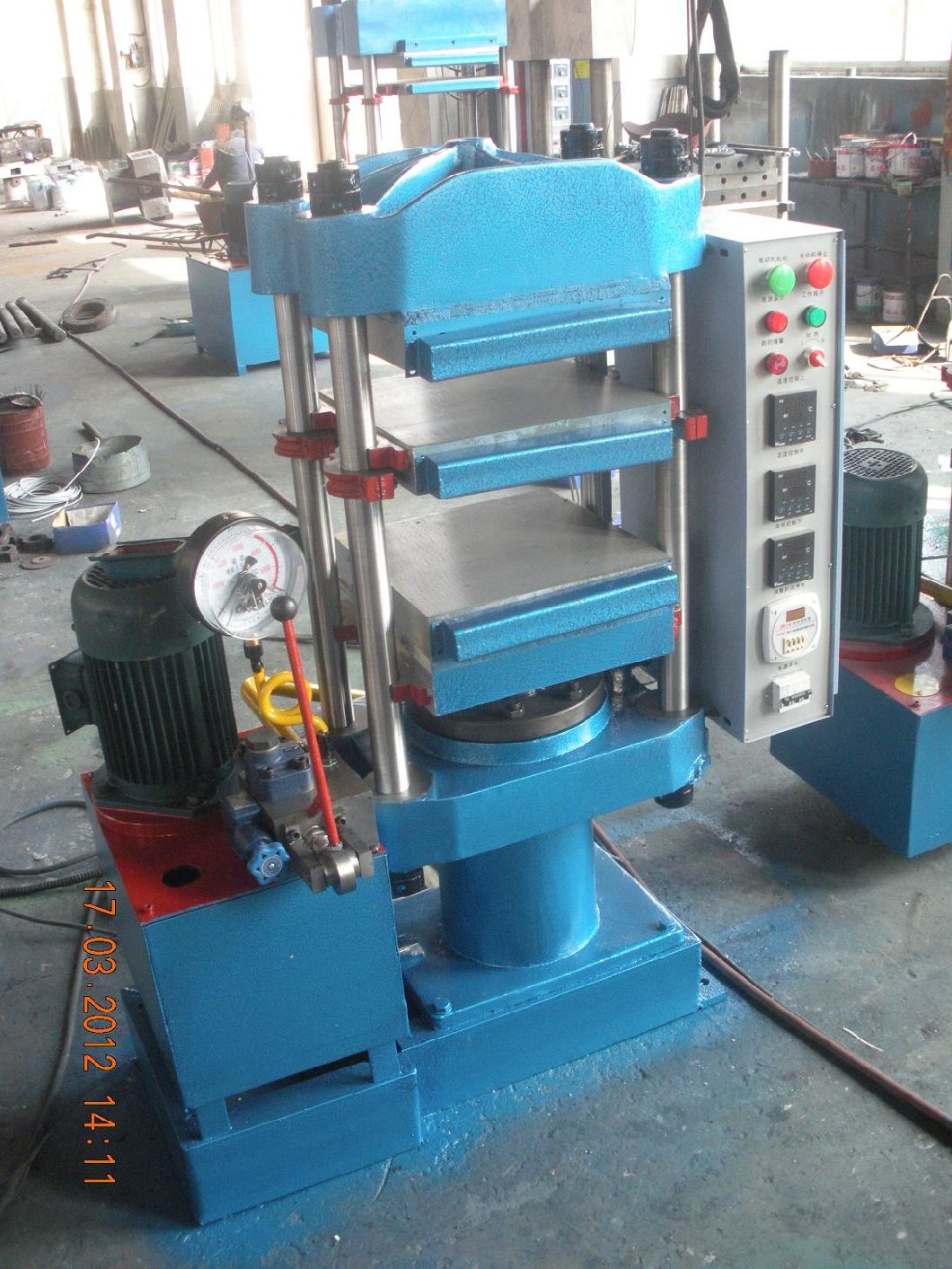

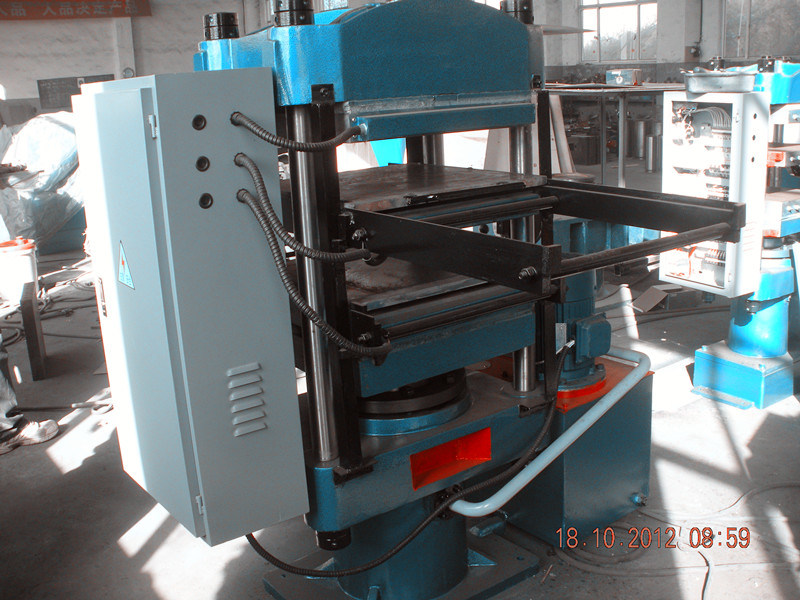

6 Machine Pictures

2 Layers (3 Hot Plates)

1 Layer (2 Hot Plates)

Digital Screen (Emergency Stop, Auto Alarm)

Optional Pull and Push Mold Installation

Note: When sending an inquiry, please provide the following details:

- What pressure do you need? 50T? 63T? 100T?

- What is the distance between the hot plates? 125mm?

- What is your hot plate size?

- Other requests like voltage, push and pull mold installation?

- Due to time zone differences, kindly include your phone number, Skype, Viber, or WhatsApp ID in the email so we can communicate quickly.

Based on these details, we can customize the machine and provide a detailed quotation along with a running video of the machine.

Packaging & Shipping

Wooden packaging or according to client’s request.

Our Services

- Overseas service: 1-2 technicians provide debugging and training for 7-14 days at a cost of $60 per day per person. You are responsible for round-trip tickets, visa, accommodation, and meals.

- During warranty period, if a quality issue arises (excluding human error), we will replace it free of charge.

- We respond within 24 hours of any problem and can resolve it through pictures or videos. If unresolved, we can send an engineer to your factory.

- We welcome you to visit our factory. We can book a hotel and pick you up at the airport. You can see our factory and observe how our machines are used in production.

- Logo design: We can create a custom logo for the machine based on your provided image.

- Original B/L: We can provide original bills of lading, commercial invoices, and packing lists, each in three copies via TNT.

- Certificate of Origin: We can supply this document to help you benefit from import tax privileges.

Company Information

Qingdao Chaoguangyue Industry Co., Ltd.

Our company has strong technical capabilities, advanced technology, excellent design, and a strict quality assurance system, earning a good reputation in the Chinese rubber machinery industry. Our main products include plate vulcanizing presses, EVA foam vulcanizing presses, open rubber mixing mills, Banbury intensive kneaders, extruders, and rubber and reclaimed rubber machinery. We can also manufacture non-standard rubber machines according to customer requirements. Our products have been sold across more than 20 provinces in China and exported to over 10 countries and regions.

With many years of production and sales experience, we strive to deliver high-quality, high-standard products. Our philosophy is: "We seek survival through quality and technology in our products, and win the market and build a reputation through integrity and brand."

Welcome to visit us!

Certification: CE, SGS, ISO9001

Welcome to contact me for pricing!

Water Wave Powder Coating,Powder Water Powder Coating,Dw Powder Coating,Texture Powder Coat

Longkou Guomei Decoration Material Co.,Ltd. , https://www.gmcoating.com